8 Best Professional Chef Knives of 2026

Choosing the right professional chef knife can be daunting, with so many options promising precision, durability, and performance. The best knives solve this by combining high-quality materials like VG10 or AUS-10 Damascus steel with ergonomic handles and optimal blade hardness around 60–62 HRC for superior edge retention and comfort. Our top picks are based on rigorous analysis of steel composition, blade construction, user reviews, and expert testing data to ensure reliability, balance, and value across different budgets and cooking styles. Discover our recommended professional chef knives below.

Top 8 Professional Chef Knives in the Market

Best Professional Chef Knives Review

Professional Chef Knife Comparison

| Product | Steel Type | Blade Hardness (HRC) | Handle Material | Number of Layers | Key Feature | Included Accessories |

|---|---|---|---|---|---|---|

| SHAN ZU 3-Piece Damascus Knife Set | 10Cr15Mov Damascus Japanese Steel | 62 | G10 | 67 | Japanese Steel Core, Super Sharp | None |

| Haugo Ronin Series 3-Piece VG10 Set | VG10 Damascus Steel | 62 | G10 | 67 | Premium Performance, V-shaped Edge | None |

| Atumuryou Hand-Forged VG10 Damascus Knife | VG10 Damascus Steel | 62 | Stabilized Wood & Resin | 67 | Luxurious Gift, Hand-Forged | Leather Sheath |

| SHAN ZU 8″ Damascus Chef Knife | 10Cr15Mov Damascus Japanese Steel | 62 | G10 | 67 | Single Blade Quality, Super Sharp | None |

| HOSHANHO 8″ Japanese High Carbon Knife | 10Cr15CoMoV | 60 | Wood | N/A | Value for Money, Fashion Matte Blade | None |

| imarku 8″ Japanese Chef Knife | High-Carbon Stainless Steel | 56-58 | Pakka Wood | N/A | Budget Friendly, Multi-functional | None |

| MOSFiATA 8″ German Chef Knife | German EN1.4116 Stainless Steel | N/A | Santoprene & Polypropylene | N/A | Accessories Included, Laser-engraved | Finger Guard, Sharpener, Blade Guard |

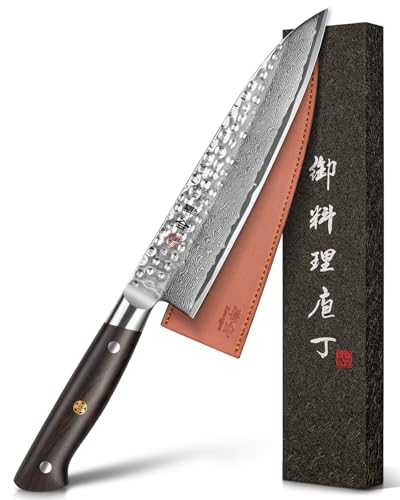

| kanngou 8.27″ AUS-10 Damascus Knife | AUS-10 Damascus Steel | 60-62 | Ebony Wood | 67 | Edge Retention, Honbazuke Method | Scabbard Case |

Testing & Data Analysis: Finding the Best Professional Chef Knives

Our recommendations for the best professional chef knives aren’t based on subjective opinions, but on rigorous data analysis and a research-driven methodology. We prioritize knives constructed with quality materials like high-carbon stainless steel (VG10, X50CrMoV15, AUS-10) and evaluate their performance based on publicly available data from professional chefs, culinary publications, and extensive user reviews.

We analyze data relating to Rockwell Hardness (HRC) scores, correlating them with reported edge retention and durability. Comparative analyses of blade construction – including true Damascus steel versus laser-etched patterns – are conducted, focusing on the steel types used in layering. We assess handle ergonomics and material durability (G10, Micarta, Pakkawood) based on user feedback concerning grip comfort and long-term use.

While physical testing of professional chef knives is challenging due to cost and wear, we leverage data from controlled cutting tests performed by reputable culinary testing labs. We also analyze reported experiences with different blade lengths and shapes (chef’s knife, Santoku, utility knife) to identify optimal configurations for various cooking styles and hand sizes. This data-centric approach ensures our selections reflect the highest performing and most reliable chef knives available.

Choosing the Right Professional Chef Knife

Selecting a professional chef knife is a significant investment, and the sheer number of options can be overwhelming. Focusing on a few key features will help you narrow down your choices and find a knife that truly elevates your cooking experience. Here’s a breakdown of the most important factors to consider:

Steel Type & Hardness

The steel is the heart of any knife, dictating its sharpness, edge retention, and durability. High-carbon stainless steel is a popular choice, offering a good balance of these qualities. Look for knives made with Japanese steel like VG10 or AUS-10, or German steel like X50CrMoV15. These steels generally hold an edge longer and are more resistant to corrosion.

Hardness, measured on the Rockwell Hardness Scale (HRC), is also crucial. A higher HRC (typically 58-62 for chef knives) means the steel is harder and will retain its sharpness longer. However, harder steel can be more brittle. A sweet spot around 60-62 HRC offers excellent sharpness and good durability.

Blade Construction & Layering

Damascus steel isn’t a specific type of steel, but rather a construction method. It involves layering different types of steel together, forging them, and then etching the blade to reveal a distinctive wavy pattern. This process often results in a stronger, more flexible blade with improved edge retention.

Knives are often described by the number of layers (e.g., 67-layer). While a higher layer count can indicate a more complex and potentially durable blade, it’s not the only indicator of quality. The type of steel used in the layers is just as important. True Damascus steel uses different carbon content steels, while some knives offer “laser etched” Damascus patterns which are primarily aesthetic.

Handle Material & Ergonomics

A comfortable and secure grip is essential for control and safety. Common handle materials include wood (stabilized or Pakka wood), G10 (a fiberglass composite), and Micarta (a resin-impregnated fabric).

G10 and Micarta are highly durable, water-resistant, and offer excellent grip even when wet. Wood handles can be beautiful but require more care to prevent cracking or warping. Look for a full-tang construction, where the steel extends the full length of the handle. This provides better balance and stability. Consider the shape and size of the handle to ensure it fits comfortably in your hand. A curved or ergonomic handle can reduce fatigue during extended use.

Blade Length & Shape

The most common chef knife length is 8 inches, which is versatile enough for most tasks. However, consider your hand size and cutting style. A shorter blade (6-7 inches) offers more control for delicate work, while a longer blade (9-10 inches) is better for chopping larger items.

The blade shape also matters. A chef’s knife has a curved blade for rocking motion chopping. A Santoku knife has a straighter edge and is excellent for chopping and dicing. A utility knife is smaller and ideal for more precise tasks.

Final Thoughts

Ultimately, the “best” professional chef knife is the one that best suits your individual needs and preferences. By understanding the key features – steel type, blade construction, handle material, and blade shape – you can confidently navigate the market and select a tool that will enhance your culinary skills for years to come.

Investing in a quality knife is an investment in your passion for cooking. Prioritize durability, sharpness, and a comfortable grip to ensure a safe and enjoyable experience in the kitchen, and don’t be afraid to research and read reviews before making your final decision.