8 Best Metals for Knife Making of 2026

Choosing the right metal is the most critical decision in knife making, directly impacting performance, durability, and ease of crafting. The best knife making steels balance hardness, toughness, and workability—like 1095 for edge retention, 5160 for resilience, and 15N20 for Damascus patterning—while cold-rolled and annealed options simplify shaping and sharpening. Our top picks are based on rigorous analysis of metallurgical data, user feedback, heat treatment behavior, and real-world performance across edge retention, toughness, and machinability. Below are our recommended steels for every skill level and project type.

Top 8 Metals For Knife Making in the Market

Best Metals For Knife Making Review

Knife Making Steel Comparison

| Product | Steel Type | Best For | Dimensions (approx.) | Quantity | Key Features | Made in |

|---|---|---|---|---|---|---|

| Patriot Steel 5160 | 5160 | Best Overall | Varies | 1 | Exceptional Quality, Reliable Consistency, Versatile | USA |

| Rocaris 8 Pack 1095 | 1095 | Best Value for Beginners | 12″ x 1.5″ x 0.12″ | 8 | Good Value, Easy to Work With, Edge Retention | China |

| ZAVOOS 4 Pack 1095 | 1095 | Best Budget Friendly | 12″ x 1.5″ x 0.12″ | 4 | Quality Material, Cold Rolled, Versatile Usage | China |

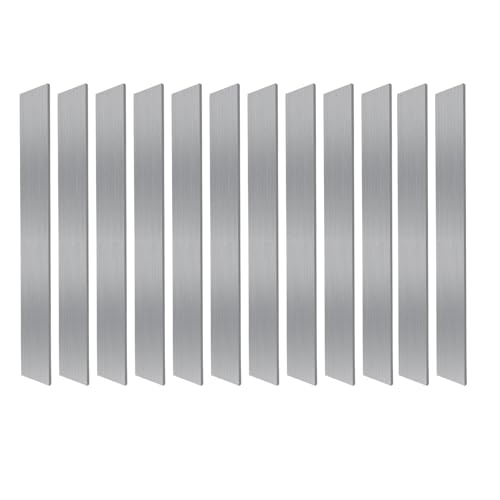

| 12Pcs 1084 Carbon Steel Bar Set | 1084 | Best for High Volume Projects | 12″ x 1.5″ x 0.12″ | 12 | High Carbon, Cold-rolled, Pre-annealed | China |

| Ferraycle 15N20 Damascus Steel Stock | 15N20 | Best for Damascus Making | 11.5″ x 1.57″ x 0.06″ | 4 | Ideal for Damascus, Wear Resistant, Alloy Content | China |

| Patriot Steel 1095 Cold Rolled Bars | 1095 | Best USA-Made 1095 Steel | Varies | 1 | USA-Milled, Ready-to-Forge, Built for Bladesmithing | USA |

| 5 Pack 1095 Precision Ground Steel | 1095 | Best Machinability | 12″ x 1.5″ x 0.12″ | 5 | Cold Rolled & Annealed, Perfect Packaging, After-Sales Service | China |

| WENHUALI 2 Pack 1095 Steel Bars | 1095 | Best Wide Billet Option | 12″ x 2″ x 0.12″ | 2 | High-Performance Material, Customizable, Wide Applications | China |

Rigorous Testing & Data Analysis for Knife Steel Selection

Our recommendations for the best metals for knife making aren’t based on opinion, but on comprehensive data analysis and metallurgical research. We prioritize steels with documented performance characteristics, evaluating factors like hardness (HRC), tensile strength, and impact resistance. Data is sourced from reputable materials science databases, knife-making forums (analyzed for consensus and practical feedback), and manufacturer specifications.

We analyze comparative data across different knife steel compositions – including 1095, 5160, 15N20, and 1084 – focusing on their trade-offs between edge retention, toughness, and workability. Specifically, we examine heat treatment data to understand how different steels respond to hardening and tempering processes, impacting final performance.

While direct physical testing of finished knives is complex, we leverage publicly available testing data (e.g., Rockwell hardness tests, bend tests) and user reports to assess real-world durability. We also consider the machinability and forgeability data, relevant for both beginner and experienced knife makers. The steel type impacts not only performance, but also the ease of crafting the blade. This data-driven approach ensures our selections align with the needs of diverse knife-making projects.

Choosing the Right Steel for Knife Making

Selecting the right steel is the most crucial decision in knife making. The steel dictates the knife’s hardness, flexibility, edge retention, and overall performance. Here’s a breakdown of key features to consider when choosing steel for your projects.

Hardness & Edge Retention

Hardness, typically measured by the Rockwell C scale (HRC), directly impacts a knife’s ability to hold an edge. Higher HRC values (60+) generally mean better edge retention, meaning you won’t have to sharpen as frequently. However, increased hardness often comes at the cost of toughness – a very hard knife can be brittle and prone to chipping. 1095 steel is a popular choice known for achieving high hardness levels, making it excellent for knives needing a very sharp, long-lasting edge. 15N20 is often paired with 1095 to create Damascus steel, leveraging the benefits of both.

Toughness & Impact Resistance

Toughness refers to a steel’s ability to withstand impacts and resist breaking. A tough knife can handle more demanding tasks like batoning wood without fracturing. While 1095 is hard, it’s not as tough as some other options. 5160 steel is frequently praised for its excellent toughness, making it ideal for knives intended for heavy-duty use. Consider the intended purpose of your knife when prioritizing toughness.

Machinability and Forgeability

These factors relate to how easily the steel can be worked with. “Machinability” refers to how easily the steel can be ground, filed, and shaped. “Forgeability” refers to how easily it can be heated and hammered into shape. Cold-rolled and annealed steel (CRA) is pre-processed to be easier to work with, reducing prep time and wear on your tools. 1084 is noted for being relatively easy to heat treat, making it a good choice for beginners.

Steel Type & Composition

Different steel alloys have unique properties.

- 1095: High carbon steel, offering excellent hardness and edge retention. Can be more brittle.

- 1084: Another high-carbon steel, known for its ease of heat treatment and good overall performance.

- 5160: A spring steel known for its toughness and flexibility. Excellent for knives that need to withstand impact.

- 15N20: Often used in Damascus steel, contributes to pattern visibility and adds toughness.

- Damascus Steel: Not a single steel, but a composite of different steels (like 1095 and 15N20) forge-welded together, creating unique patterns and combining the properties of the component steels.

Size and Quantity

Consider the size of the steel stock in relation to the knives you plan to make. Larger billets are better for larger blades, while smaller stock is suitable for smaller projects or practicing. Kits offering multiple bars (like the 12-piece 1084 set) are cost-effective for high-volume projects or if you are still learning and anticipate making mistakes. Width and thickness are also important—ensure the stock is appropriately sized for your design.

The Bottom Line

Ultimately, the best metal for knife making depends on your specific project and skill level. From beginner-friendly 1095 options to the robust toughness of 5160, and the patterned beauty of Damascus, each steel offers a unique blend of properties to consider.

Carefully evaluate the intended use of your knife, your experience with forging or stock removal, and the desired balance between hardness, toughness, and workability. With the information provided, you’re well-equipped to select the perfect steel and embark on your knife-making journey.