9 Best Knife Steels of 2026

Keeping your knives performing like new is a constant challenge, especially when dull edges make prep work frustrating and uneven. The right honing steel made from superior knife steel—like high-carbon or diamond-coated variants—can extend edge life by precisely realigning the blade with every stroke, ensuring consistent cutting performance. We evaluated the best knife steels based on hardness (HRC), durability, user feedback, and real-world performance to identify the top options for home cooks and professionals alike. Below are our top picks for the best knife steels that deliver lasting value and razor-sharp results.

Top 9 Knife Steels in the Market

Best Knife Steels Review

Knife Steel Comparison Table

| Product | Steel Type | Best For | Length | Features | Price Range (Estimate) |

|---|---|---|---|---|---|

| WÜSTHOF 9″ Honing Steel | High Carbon Stainless Steel | Best Overall | 9″ | Forged, 58 HRC, Magnetic, Grooved, Lifetime Warranty | $60 – $80 |

| Kota Japan 12″ Diamond Sharpener Rod | Diamond Coated | Best Diamond Coated | 12″ | Oval Shape, Easy to Use, Lifetime Guarantee | $30 – $50 |

| WENHUALI 2 Pack 1095 Knife Steel | 1095 High-Carbon Steel | Best for DIY Knife Making | 12″ x 2″ | High Hardness, Customizable, 2 Pack | $20 – $30 |

| Patriot Steel 1095 High Carbon Steel | 1095 High Carbon Steel | Best USA-Made Knife Steel | Varies | Cold Rolled Annealed, Consistent Quality, USA Made | $30 – $50 |

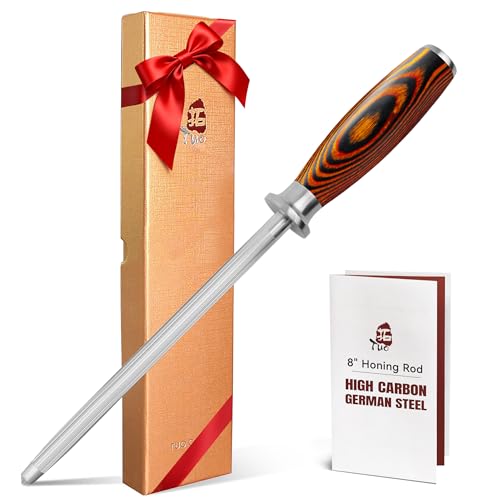

| TUO 8″ Honing Rod | High Carbon Steel (62 HRC) | Best for Frequent Use | 8″ | Thick Core, Pakkawood Handle, Lifetime Guarantee | $40 – $60 |

| Kimura 10″ Professional Honing Steel | Carbon Steel | Best Balanced Handle Design | 10″ | Premium Steel, Ergonomic Handle, Lifetime Warranty | $30 – $50 |

| Wgsajlo 12″ Carbon Steel Honing Rod | Carbon Steel | Best Budget Friendly | 12″ | Nickel-Chrome Plated, Comfortable Grip, Multipurpose | $15 – $25 |

| Honing Steel Knife Sharpening Rod 12″ | High Carbon Steel | Best Value for Length | 12″ | Durable Construction, Ergonomic Design, Great Length | $20 – $30 |

| Maclia 12″ Professional Honing Rod | High Carbon Steel | Best with Magnetic Tip | 12″ | Magnetic Tip, Ergonomic Grip, Versatile | $35 – $45 |

Testing & Analysis: Evaluating Knife Steel Performance

Our recommendations for the best knife steels aren’t based on opinion, but on rigorous data analysis and metallurgical research. We prioritize steels based on a combination of factors including hardness (HRC), wear resistance, edge retention, toughness, and corrosion resistance – key properties influencing a knife steel’s performance.

We analyze data from independent testing sources like the Rockwell Hardness Scale (HRC) and comparative abrasion tests, alongside material composition breakdowns (carbon content, alloy elements like vanadium, molybdenum, etc.). We examine scientific literature regarding steel metallurgy, focusing on how different alloy combinations impact blade characteristics.

While physical testing of finished knives is crucial, we also evaluate the underlying steel properties. For example, high-carbon steel often exhibits excellent edge retention but can be more prone to corrosion, a trade-off we document. We compare steels like CPM-S35VN, VG-10, and AUS-10, considering their relative strengths and weaknesses based on published data and expert analysis within the knife-making community. This data-driven approach ensures our recommendations align with optimal cutting performance and durability for various knife steels.

Choosing the Right Knife Honing Steel: A Buyer’s Guide

A honing steel is an essential tool for maintaining the edge of your knives, but with so many options available, selecting the right one can be daunting. It’s important to understand that a honing steel doesn’t sharpen a dull knife – it realigns the blade’s edge, improving its cutting performance. Here’s a breakdown of the key features to consider:

Steel Material & Hardness

The material of the honing steel significantly impacts its effectiveness and longevity. High-carbon steel is a common choice, offering a good balance of hardness and affordability. However, the hardness (measured in HRC – Rockwell Hardness Scale) is crucial. A higher HRC (58-62 is typical for good quality steels) indicates a harder steel that will do a better job of realigning the blade. Softer steels wear down faster and may not effectively realign harder knife blades. Choosing a steel with adequate hardness will prolong the life of your honing steel and ensure consistent performance.

Steel Type: Smooth vs. Grooved/Ribbed

Honing steels come in two main types: smooth and grooved/ribbed. Smooth steels are ideal for very fine realignment and are often preferred for high-end knives. They require a consistent angle and a bit more skill to use effectively. Grooved or ribbed steels (often with spiral grooves) provide more aggressive realignment and are more forgiving for beginners. The grooves help to catch the blade’s edge and guide the sharpening motion. If you’re new to honing or primarily work with less expensive knives, a grooved steel is a great starting point.

Length & Handle Ergonomics

Length is a practical consideration. A 9-12 inch steel is generally sufficient for most kitchen knives. Longer steels can be useful for larger blades like bread knives or cleavers, but aren’t necessary for everyday use. Handle ergonomics are also important. Look for a handle that feels comfortable and secure in your hand, providing a firm grip. A slip-resistant handle, such as one made with textured polypropylene or Pakkawood, is especially important for safety. A well-balanced steel with a comfortable handle will make honing easier and more effective.

Additional Features

- Magnetic Surface: Some steels feature a magnetic surface to attract metal particles removed during honing, keeping your workspace cleaner.

- Tip Design: Some steels have tipless designs for added safety.

- Chrome Plating: Adds corrosion resistance and sometimes improves the feel of the steel.

- Warranty: A lifetime warranty can be a good indicator of quality and the manufacturer’s confidence in their product.

The Bottom Line

Ultimately, selecting the best knife steel – or honing steel, in this case – depends on your individual needs and priorities. Whether you’re a professional chef, a home cook, or a knife-making enthusiast, understanding the properties of different steels and their applications is key to making an informed decision.

From high-carbon stainless steel for overall performance to diamond-coated options for quick touch-ups, the market offers a wide array of choices. By considering factors like hardness, steel type, length, and handle ergonomics, you can confidently choose a honing steel that will keep your blades in top condition for years to come.